|

Red LED Flashlight Modification |

|

|

|

A simple replacement for the existing lamp capsule in the

flashlight. Good for Red, Yellow, and Green LEDs. Uses the

lathe. |

| While I

was prospecting for a new bulb for the flashlight, I found that the local

suppliers no longer carried the flashlight, let alone the bulb assembly.

I found that to be rather annoying. The original flashlight has a

plastic lamp assembly with a metallized plastic reflector. The bulb is

hard wired into the assembly, making replacement rather difficult.

Since I was annoyed, and it was time for a project, I picked

the brightest LED I could find. Now I do have both white, blue, and UV

LEDs as well as the standard complement of red, yellow, and green. The

main difficulty is that the flashlight uses 2 AAA batteries, and that means

that we get 3.0 volts. This will do a good job on red, yellow, and

green LEDs, which have a forward voltage of roughly 1.6 to 2.6 volts, but do

a miserable job on white, blue, and UV LEDs. Looks like this design is

going to be good for the red, yellow, and green ones. I could always

add another battery, but that might be a bit more effort than I want. |

|

First, a picture of

the original lamp assembly. it's the lower one. The bits and

pieces of the new assembly are around it. |

|

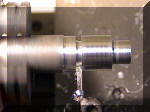

First, turn down

the outer diameter of the lamp assembly. Next turn down the minor

diameter for the neck portion. Not shown, but needed, is a hole

through the whole assembly (and this is not that hole being drilled) that

fits the outside of the LED, but is not big enough for the flange.

Next, and this is what you see, you counterdrill the hole. This is a

1/4 inch drill which takes you roughly to the beginning of the wide part.

The neck is sized the same as the existing neck, you have to use the

existing spring and washer. |

|

Pick the desired

length of the large section, then use the parting tool to cut the assembly

off. At this point, also not shown, you reverse the lamp holder in the

lathe, then countersink the hole with a countersink. This will provide

a reflector. It's conical, and not parabolic, but it will do as a

reflector for now. |

|

Take a 3/8 rod of

Delrin, then cut down the outside so that it is the diameter of the smaller

part of the lamp housing. |

|

Drill and tap the

center section for 6-32. Make the tapped part deep enough to go

through the entire assembly. You want the stepped portion to be about

0.15 long, and the overall length will make the assembly the same length as

the whole light assembly. |

|

This is one with

the neck too short, and the delrin section too long. Built this way,

it leaves less space inside the assembly for resistors and connectors than

you want. (especially if you want to put a regular bulb in there). |

|

The center contact

is made from a 6-32 brass screw. Turn the head roughly flat, and drill

down the center of the screw with a #52 drill. That will be a space

for the lead from the resistor. |

|

Here's how the

thing goes together. The first one that I built allowed for not enough

room for an incandescent lamp, but enough for the LED. Note that the

screw has been cut down considerably in length. The LED cathode lead

is pinched between the delrin and the aluminum reflector. There is a

small flat filed on the delrin part to give space to the lead. |

|

The upper is the

original assembly, the lower one is the new assembly. |

|

The slightly

redesigned and repositioned lamp assembly. Note that the delrin

section is much shorter, the fat part is only 0.1 inch long, the whole

delrin piece is about 0.25 inches. You can clearly see the hole

through the brass screw. |

|

Well, here it is,

properly working. Even through the light looks white, it isn't, the

camera is just a bit overloaded here. |

|

The flashlight that all this goes into. |

|

Overall, an easy and

quick project. I'm limited in color choices by battery voltage, but

overall, the light, at 5000 mCD is not doing badly at all. I'd prefer

white, but that's another project. |